Aircraft Electrical Wiring

This advice on routing and installing aircraft

electrical

wiring is specific to construction of a Vans RV-8, but builders of

other kitplanes will also find it useful.

For the most part, my

wire routing is from the front right firewall where my battery is

located, to the circuit breakers on the F-8101 right console.

Then forward into the right gear box, across the F-802T L.G. box upper

brace, into the left gear box and to the switches on the throttle

quadrant.

From there they run through the left gear box, under the F-881PP-L mid

cabin cover, through the main wing spar, and back the left side of the

aircraft.

I ran my aircraft electrical wiring for the wing tank

senders down the respective right gear boxes, then under the

mid

cabin panels, and out the side of the fuselage to the tanks.

I

used a small rubber grommet for the hole through the fuselage.

I’m

happy with the way the wiring turned out, except for right behind the

panel. If I were doing it again, I would change my aircraft

electrical wiring slightly to make removing the main panel

easier.

(See

what I would do different)

My Wire Routing

Wire bundle just aft of gear box

Aft cabin

floor wires

Flap wire and

GPS antenna

Forward right

wires

Two images of the wiring bundle just aft of the main spar

Aft fuselage

wires

Forward left

wires

There were two spots that were a little difficult

to work with while running the wires. Here are some thoughts

on them.

Bottom of the gear boxes

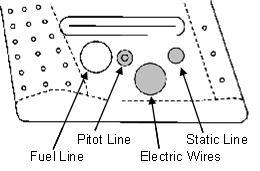

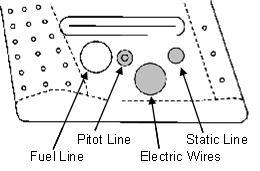

Because

I needed the return fuel line, I enlarged the hole at the bottom of the

F-802B-L bulkhead. When I ran the aircraft electrical wiring,

I

thought the extra hole I made would be enough. That wasn’t

the

case. I later realized the electric and pitot/static lines

wouldn’t all fit, and I would have to cut more holes. Had I

known

from the beginning how much stuff was going to run through here, I

would have made the hole bigger to start with, and could have achieved

a much cleaner look. Because

I needed the return fuel line, I enlarged the hole at the bottom of the

F-802B-L bulkhead. When I ran the aircraft electrical wiring,

I

thought the extra hole I made would be enough. That wasn’t

the

case. I later realized the electric and pitot/static lines

wouldn’t all fit, and I would have to cut more holes. Had I

known

from the beginning how much stuff was going to run through here, I

would have made the hole bigger to start with, and could have achieved

a much cleaner look.

I have two ideas how this could be done

better. The first is to make one hole large enough for

everything. The fuel lines would run through on their

own.

I would then use an adel clamp to hold the electric wires, and one each

for the pitot and static lines.

The

other idea is to make

several holes. But if this is planned out from the beginning,

they can be made the right size and location before the gearbox is

riveted together, or if it’s too late for that, drilled before anything

is installed. Two small holes with a rubber grommet would

each

hold the pitot and static lines. A third hole, slightly

larger,

again with the rubber grommet, would hold the aircraft electric

wiring. The fourth hole would allow the fuel lines to run

forward. The

other idea is to make

several holes. But if this is planned out from the beginning,

they can be made the right size and location before the gearbox is

riveted together, or if it’s too late for that, drilled before anything

is installed. Two small holes with a rubber grommet would

each

hold the pitot and static lines. A third hole, slightly

larger,

again with the rubber grommet, would hold the aircraft electric

wiring. The fourth hole would allow the fuel lines to run

forward.

Of course, a combination could also be

used. You can combine items into one hole and use clamps to

hold

things off the edges. Be careful not to squish the

pitot/static

lines.

Aft end of the main spar

I

followed Vans instructions and drilled the electric and pitot/static

holes as described on plans OP-11 DETAIL G and DETAIL H. I

then

strung the corrugated conduit through the spar and aft under the

floor. There was no problem until I installed the W-816

aileron

pushrods. The conduit interfered and rubbed against the

pushrods

as they moved. I had to cut the conduit away so I could bend

the

wire bundle tight enough to keep it from rubbing. I turned it

90°

and clamped it to the spar, then ran it under the pushrods. I

followed Vans instructions and drilled the electric and pitot/static

holes as described on plans OP-11 DETAIL G and DETAIL H. I

then

strung the corrugated conduit through the spar and aft under the

floor. There was no problem until I installed the W-816

aileron

pushrods. The conduit interfered and rubbed against the

pushrods

as they moved. I had to cut the conduit away so I could bend

the

wire bundle tight enough to keep it from rubbing. I turned it

90°

and clamped it to the spar, then ran it under the pushrods.

Aft end of

the main spar after corrections

Return

from Aircraft Electrical

Wiring to Aircraft

Electrical Systems

Return

from Aircraft Electrical

Wiring to Kit

Plane Advice Home

|

Because

I needed the return fuel line, I enlarged the hole at the bottom of the

F-802B-L bulkhead. When I ran the aircraft electrical wiring,

I

thought the extra hole I made would be enough. That wasn’t

the

case. I later realized the electric and pitot/static lines

wouldn’t all fit, and I would have to cut more holes. Had I

known

from the beginning how much stuff was going to run through here, I

would have made the hole bigger to start with, and could have achieved

a much cleaner look.

Because

I needed the return fuel line, I enlarged the hole at the bottom of the

F-802B-L bulkhead. When I ran the aircraft electrical wiring,

I

thought the extra hole I made would be enough. That wasn’t

the

case. I later realized the electric and pitot/static lines

wouldn’t all fit, and I would have to cut more holes. Had I

known

from the beginning how much stuff was going to run through here, I

would have made the hole bigger to start with, and could have achieved

a much cleaner look. The

other idea is to make

several holes. But if this is planned out from the beginning,

they can be made the right size and location before the gearbox is

riveted together, or if it’s too late for that, drilled before anything

is installed. Two small holes with a rubber grommet would

each

hold the pitot and static lines. A third hole, slightly

larger,

again with the rubber grommet, would hold the aircraft electric

wiring. The fourth hole would allow the fuel lines to run

forward.

The

other idea is to make

several holes. But if this is planned out from the beginning,

they can be made the right size and location before the gearbox is

riveted together, or if it’s too late for that, drilled before anything

is installed. Two small holes with a rubber grommet would

each

hold the pitot and static lines. A third hole, slightly

larger,

again with the rubber grommet, would hold the aircraft electric

wiring. The fourth hole would allow the fuel lines to run

forward.  I

followed Vans instructions and drilled the electric and pitot/static

holes as described on plans OP-11 DETAIL G and DETAIL H. I

then

strung the corrugated conduit through the spar and aft under the

floor. There was no problem until I installed the W-816

aileron

pushrods. The conduit interfered and rubbed against the

pushrods

as they moved. I had to cut the conduit away so I could bend

the

wire bundle tight enough to keep it from rubbing. I turned it

90°

and clamped it to the spar, then ran it under the pushrods.

I

followed Vans instructions and drilled the electric and pitot/static

holes as described on plans OP-11 DETAIL G and DETAIL H. I

then

strung the corrugated conduit through the spar and aft under the

floor. There was no problem until I installed the W-816

aileron

pushrods. The conduit interfered and rubbed against the

pushrods

as they moved. I had to cut the conduit away so I could bend

the

wire bundle tight enough to keep it from rubbing. I turned it

90°

and clamped it to the spar, then ran it under the pushrods.