|

Aircraft Throttle Quadrant

This homebuilt aircraft throttle quadrant

contruction advice is based on my customized quadrant for a Vans RV-8.

However,

builders of any kitplane will find ideas here that apply to them.

Why

customize?

I

have short arms, and found the standard location of the aircraft

throttle was

too far forward and outboard. It was too uncomfortable for me

to

reach, so I felt like I was stretching to get to it. Since

it’s

my plane, it should fit me. I teamed with a friend

of mine

who also suffers from the same affliction, and we came up with our own

throttle quadrant that moved the throttle inboard and aft just enough

to make it comfortable. I

have short arms, and found the standard location of the aircraft

throttle was

too far forward and outboard. It was too uncomfortable for me

to

reach, so I felt like I was stretching to get to it. Since

it’s

my plane, it should fit me. I teamed with a friend

of mine

who also suffers from the same affliction, and we came up with our own

throttle quadrant that moved the throttle inboard and aft just enough

to make it comfortable.

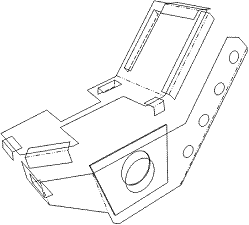

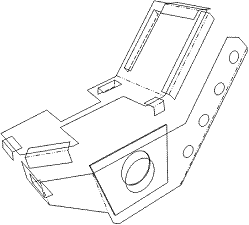

Building the

Aircraft Throttle

Quadrant

We

started with the F-864BPP Throttle Quadrant Cover as a template for our

cover. Using posterboard, we marked the F-864BPP, then added

the

extra thickness for the F-804 channel. We left it long enough

in

the front to play with. We then put it into the cockpit and

messed with the front until we were happy with the look as it mated to

the bottom of the F-803BPP-L Instrument Sub Panel. This gave

us

the angle for the front of the cover. We

started with the F-864BPP Throttle Quadrant Cover as a template for our

cover. Using posterboard, we marked the F-864BPP, then added

the

extra thickness for the F-804 channel. We left it long enough

in

the front to play with. We then put it into the cockpit and

messed with the front until we were happy with the look as it mated to

the bottom of the F-803BPP-L Instrument Sub Panel. This gave

us

the angle for the front of the cover.

To make the

side, we

traced the F-864 onto posterboard. The top was cut to shape

to

match the cover, and the bottom was cut to fit over the F-806A-L

forward arm rest. The slant was cut to a pleasing thickness,

lightening holes drilled, and the bottom turned in to provide rigidity.

The

cover is held to the side by an aluminum angle flush riveted to the

back sides of both. We then cut the F-864 to fit on the

inside of

the new cover and provide extra support to the throttle

assembly.

We did have to install longer screws into the four corners of the

throttle assembly since they were now going through the new cover and

what was left of the F-864.

Support and

attaching

We

used AA3-032 ¾ x ¾ to secure the outside to the skin above the F-864C.

More of the same AA was used to secure the front to the bottom of the

F-803BPP-L Instrument Sub Panel, and the back to the F-806A-L Forward

Arm Rest. We riveted all of the AA in place, and installed

nutplates to hold the aircraft throttle quadrant.

To support

the bulk of

the weight, we used some 2 x 2 ½ x 3/16 6061-T6 leftover from the T-405

tank attachment angle. My friend riveted his to the

F-804PP-L,

and I bolted mine. Two pieces of 3/16 aluminum angle are

riveted

to the side of the throttle quadrant to match up to the top of the

6061-T6 bracket. Two bolts secure the throttle quadrant to

the

bracket.

Rear

Seat Throttle Linkage

Because

I had moved the front throttle, the linkage to the rear seat needed

modifying too. I started by drilling the holes in the F-805-L

bulkhead as depicted in Template #1 provided with the Rear Seat

Throttle Kit. I bent a piece of scrap ¼ inch tubing to get

the

rough shape I wanted. I used this piece of tubing to enlarge

the

hole as needed until it could travel freely without scraping.

It

took a lot of cycles of bend a little, enlarge the hole, bend a little

more until I got the hole large enough, and the tubing bent correctly. Because

I had moved the front throttle, the linkage to the rear seat needed

modifying too. I started by drilling the holes in the F-805-L

bulkhead as depicted in Template #1 provided with the Rear Seat

Throttle Kit. I bent a piece of scrap ¼ inch tubing to get

the

rough shape I wanted. I used this piece of tubing to enlarge

the

hole as needed until it could travel freely without scraping.

It

took a lot of cycles of bend a little, enlarge the hole, bend a little

more until I got the hole large enough, and the tubing bent correctly.

I

was finally happy with the look and fit, so I made the F-8114B pushrod

by copying the tubing with the correct 5/16 O.D. 6061-T6

tube.

Then I threaded the ends and installed the AN316-4R Jam-nuts, the

MS21252-4RS Clevis, and the M34-14 Rod end bearing as depicted in

drawing OP-2.

When

I first hooked it all

up, the

MS212532-4RS Clevis was bottoming out on the front throttle lever

before the lever was in the idle position. It took a little

extra

bend to get it to fit without interference. It’s hard to tell

from the pictures, but the pushrod stays pretty tight to the fuselage

skin until just aft of the F-804 channel, then it turns inboard and up

into the front throttle lever. When

I first hooked it all

up, the

MS212532-4RS Clevis was bottoming out on the front throttle lever

before the lever was in the idle position. It took a little

extra

bend to get it to fit without interference. It’s hard to tell

from the pictures, but the pushrod stays pretty tight to the fuselage

skin until just aft of the F-804 channel, then it turns inboard and up

into the front throttle lever.

Return

from Aircraft Throttle

Quadrant to Other

Mods

Return from Aircraft Throttle Quadrant

to Kit Plane Advice Home

|

I

have short arms, and found the standard location of the aircraft

throttle was

too far forward and outboard. It was too uncomfortable for me

to

reach, so I felt like I was stretching to get to it. Since

it’s

my plane, it should fit me. I teamed with a friend

of mine

who also suffers from the same affliction, and we came up with our own

throttle quadrant that moved the throttle inboard and aft just enough

to make it comfortable.

I

have short arms, and found the standard location of the aircraft

throttle was

too far forward and outboard. It was too uncomfortable for me

to

reach, so I felt like I was stretching to get to it. Since

it’s

my plane, it should fit me. I teamed with a friend

of mine

who also suffers from the same affliction, and we came up with our own

throttle quadrant that moved the throttle inboard and aft just enough

to make it comfortable.

Because

I had moved the front throttle, the linkage to the rear seat needed

modifying too. I started by drilling the holes in the F-805-L

bulkhead as depicted in Template #1 provided with the Rear Seat

Throttle Kit. I bent a piece of scrap ¼ inch tubing to get

the

rough shape I wanted. I used this piece of tubing to enlarge

the

hole as needed until it could travel freely without scraping.

It

took a lot of cycles of bend a little, enlarge the hole, bend a little

more until I got the hole large enough, and the tubing bent correctly.

Because

I had moved the front throttle, the linkage to the rear seat needed

modifying too. I started by drilling the holes in the F-805-L

bulkhead as depicted in Template #1 provided with the Rear Seat

Throttle Kit. I bent a piece of scrap ¼ inch tubing to get

the

rough shape I wanted. I used this piece of tubing to enlarge

the

hole as needed until it could travel freely without scraping.

It

took a lot of cycles of bend a little, enlarge the hole, bend a little

more until I got the hole large enough, and the tubing bent correctly. When

I first hooked it all

up, the

MS212532-4RS Clevis was bottoming out on the front throttle lever

before the lever was in the idle position. It took a little

extra

bend to get it to fit without interference. It’s hard to tell

from the pictures, but the pushrod stays pretty tight to the fuselage

skin until just aft of the F-804 channel, then it turns inboard and up

into the front throttle lever.

When

I first hooked it all

up, the

MS212532-4RS Clevis was bottoming out on the front throttle lever

before the lever was in the idle position. It took a little

extra

bend to get it to fit without interference. It’s hard to tell

from the pictures, but the pushrod stays pretty tight to the fuselage

skin until just aft of the F-804 channel, then it turns inboard and up

into the front throttle lever.