Canopy

For me, installing the

canopy was the scariest part of

building my RV-8. I

think I was nervous

because there was a point of no return once I start cutting the bubble

in two,

and if I made a mistake I would have to spend another $1000. But I took it slow and

made sure I was ready

for the next step before I started, and it turned out fine.

Slide Rails

I

drilled and screwed the

C-804/C-805 canopy rail completely

on at this point. Then

when I had

finished the installation, I found that the anchor pin on

the frame that fits into the C-806 anchor block scraped the

top of the rail. So

I had to remove it and

grind down the top

just a little. If I

were doing it again,

I would only put in a few of the screws that hold the rail in place,

making it

easier to remove later if needed. I

drilled and screwed the

C-804/C-805 canopy rail completely

on at this point. Then

when I had

finished the installation, I found that the anchor pin on

the frame that fits into the C-806 anchor block scraped the

top of the rail. So

I had to remove it and

grind down the top

just a little. If I

were doing it again,

I would only put in a few of the screws that hold the rail in place,

making it

easier to remove later if needed.

I know you

aren’t ready to paint the side rails yet, but

since I am on the subject of rails, I’ll mention it now. I painted mine, and I

believe I will have to

constantly maintain the paint job as it gets worn by entering and

exiting the

cockpits. I have

since seen some side

rails that were just polished aluminum, and they looked really good. If I were doing it again,

I would not paint

my rails; I would just polish them.

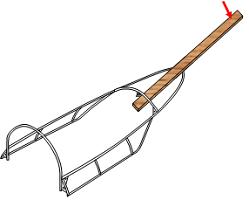

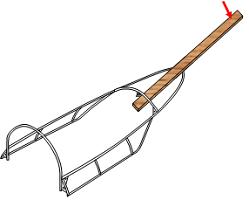

Canopy Frame

I spent a lot of time

working the frame to fit as close as

possible all the way around. I

started

at the front and worked my way back.

But

when I made a tweak at the rear, it often effected the front. I was able to make some of

the tweaks with

just my hands, but when it came to the aft end of the frame, I needed

more leverage. I

used a 2x4 below the rail next to the

WD-640H and above the aft rail to bend the aft rail down enough to get

the ¾ to 5/8 inch gap above the C-804 slide cap. I spent a lot of time

working the frame to fit as close as

possible all the way around. I

started

at the front and worked my way back.

But

when I made a tweak at the rear, it often effected the front. I was able to make some of

the tweaks with

just my hands, but when it came to the aft end of the frame, I needed

more leverage. I

used a 2x4 below the rail next to the

WD-640H and above the aft rail to bend the aft rail down enough to get

the ¾ to 5/8 inch gap above the C-804 slide cap.

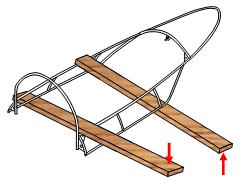

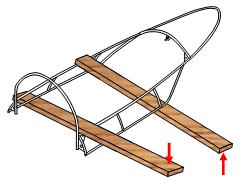

I

also needed the 2x4s to remove a little bit of a twist that was in the

frame. Initially

one side of the frame

was higher above the fuselage that the other side.

So I put one 2x4 over the left side and below

the right side at the front of the frame and another under the left

side and

over the right at the rear of the frame.

Then I pulled one up and the other down to

twist the frame. I

also needed the 2x4s to remove a little bit of a twist that was in the

frame. Initially

one side of the frame

was higher above the fuselage that the other side.

So I put one 2x4 over the left side and below

the right side at the front of the frame and another under the left

side and

over the right at the rear of the frame.

Then I pulled one up and the other down to

twist the frame.

I kept working the frame

until I had:

- All six

temporary .040 strips touching the fuselage, one at each down tube on

the frame

- The lower

frame rail parallel to the slide rail

- The aft end

of the frame the required ¾ to 5/8 inch gap above the C-804

slide

cap

Aft Canopy Stop

Before you permanently

install the side rails, think about a

stop for the aft end. If

you don’t put

something there, the canopy will slide all the way aft until the handle

hits

the F-807 bulkhead.

I have seen two clean,

cheap and easy stops. One

was just a bolt and nut installed through

the C-803 side rail. The

nut was inside

the rail, and stopped the C-658 roller from going any farther aft. I initially tried this

with a bolt in the

hole I had to drill for the aft most screw shown in Detail B, DWG 44. This worked great until I

installed the

handle and discovered it wasn’t far enough forward. I have seen two clean,

cheap and easy stops. One

was just a bolt and nut installed through

the C-803 side rail. The

nut was inside

the rail, and stopped the C-658 roller from going any farther aft. I initially tried this

with a bolt in the

hole I had to drill for the aft most screw shown in Detail B, DWG 44. This worked great until I

installed the

handle and discovered it wasn’t far enough forward.

The second stop I have

seen is just a short piece of rubber

hose slipped inside the side rail.

You

will have to slip it in before final installation.

The diameter of the hose was large enough to

keep it from falling out, and it was long enough to stop the C-658

roller

before the handle hit the F-807 bulkhead.

Now that the canopy frame

is done, let's look at the actual plexiglass

bubble.

Return

from Canopy

to Finishing Kit

Return from Canopy to Kit Plane Advice Home

|

I

drilled and screwed the

C-804/C-805 canopy rail completely

on at this point.

I

drilled and screwed the

C-804/C-805 canopy rail completely

on at this point. I spent a lot of time

working the frame to fit as close as

possible all the way around.

I spent a lot of time

working the frame to fit as close as

possible all the way around. I

also needed the 2x4s to remove a little bit of a twist that was in the

frame.

I

also needed the 2x4s to remove a little bit of a twist that was in the

frame. I have seen two clean,

cheap and easy stops.

I have seen two clean,

cheap and easy stops.