Wing RivetingThis wing riveting advice is specific to the Vans RV-8. However, it could also prove valuable to builders of other Vans kits or other aluminum kitplanes. Scarfing the Wing Skins

Now you can dimple the skins. Make sure you spend some extra time on these corners when you are priming. Because you have removed the alclad coating, these corners are more susceptible to corrosion. Leading Edge

You will assemble the leading edge in the cradle you used earlier to fit and drill. Now put the entire leading edge assembly onto the wing spar. By reaching in through the leading edge spar lightening holes, you can buck the rivets to attach the ribs to the main spar.

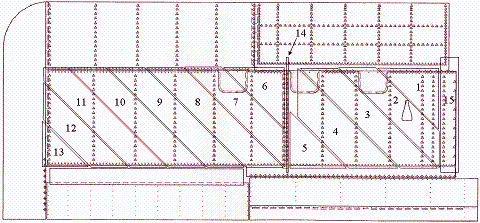

Riveting the Top Skins I can’t see that the skin would move or buckle if you installed the rivets in any order, but I followed Vans wing riveting recommendation to rivet from the center of each rib, for and aft. As I got close to the top and bottom of the rib, I started alternating between the rib and the spar. By riveting back and forth, I finished the rib as I finished the rivets on the spars behind the rib I was working on. This continued to the end of the wing. I had a friend help me backrivet the top skins. I drove the rivets, and had him hold the bucking bar. So all the skilled work was up to me, and I had only myself to blame if there was a mistake. To make the process go faster, I marked the rivet callouts on the wing skin plastic coating next to the rivet holes. That way as we were riveting, we didn’t have to stop and refer to the drawing. Top

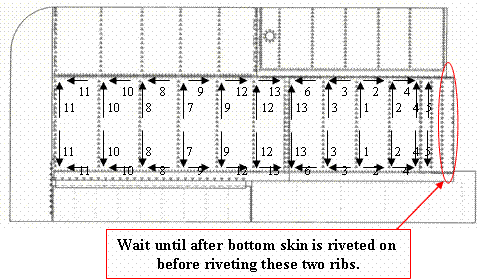

Wing Skin Rivet Sequence Initially, I had pulled the electric conduit all the way through the rib holes before I started riveting. But I found that it got in the way, and had to remove it. I ended up pulling it through the wing as I worked my way down with the rivets. That way it was easy to get to, but it was out of my way as I riveted. Bottom

Wing Skin Rivet Sequence

Click Image to Enlarge

I left my wings in the jig to install the aileron brackets, aileron gap fairings, flap braces, and bottom skins. When I finally got around to the left wing bottom skins, I riveted them in the cradle. I found it a lot easier to do it vertically than trying to have two people reach over the bench. This completed the wing riveting process. Next is ailerons and flaps.

Return from Wing Riveting to Wing Kit Return from Wing Riveting to Kit Plane Advice Home |

You

start the

wing riveting

process by preparing

the wing skins.

You

start the

wing riveting

process by preparing

the wing skins. Then

I

began in earnest to

file the corner down.

Then

I

began in earnest to

file the corner down. The

wing riveting directions would

have you wait

until the leading edge

assembly is riveted to the wing before installing leading edge

landing/taxi

lights (See

The

wing riveting directions would

have you wait

until the leading edge

assembly is riveted to the wing before installing leading edge

landing/taxi

lights (See